The international ITER fusion project is building “a sun on earth” that will produce a self-heated, burning plasma—a key step toward industrial-scale fusion energy production. Controlling that plasma can be tricky, though, because disruptions may occur that cool and collapse the plasma. Sudden losses of plasma energy and current have the potential to erode plasma-facing components inside the ITER vacuum vessel. US ITER researchers based at the Department of Energy’s Oak Ridge National Laboratory are leading the development of a disruption mitigation system to reduce the effects of plasma disruptions. The United States Domestic Agency for ITER, one of seven international partners, signed a formal arrangement with the ITER Organization on July 29 for the work.

“We have a very conservative and flexible approach to disruption mitigation on ITER,” said Larry Baylor, a distinguished scientist in plasma technologies and applications at ORNL, “with different locations for material to be injected, different types of material, and different response times. We are also designing the system in a way that will allow for evolution of the mitigation technology.”

Two approaches have been developed to help reduce the effects of plasma disruptions: Massive gas injection and shattered pellet injection. Both deliver material to the plasma within milliseconds. By injecting material to the plasma, ITER operators will be able to manage plasma energy in a way that lessens thermal loads and mechanical stresses on the plasma-facing components of the machine. The injected material can also inhibit the formation of runaway electrons, which occur when electrons are accelerated by the electric field in the plasma during a disruption.

The gas will be neon, argon, deuterium or helium; the pellets will typically be composed of neon with a deuterium outer layer. The pellets are shattered against a plate as they enter the vacuum vessel in order to better disperse the material into the plasma.

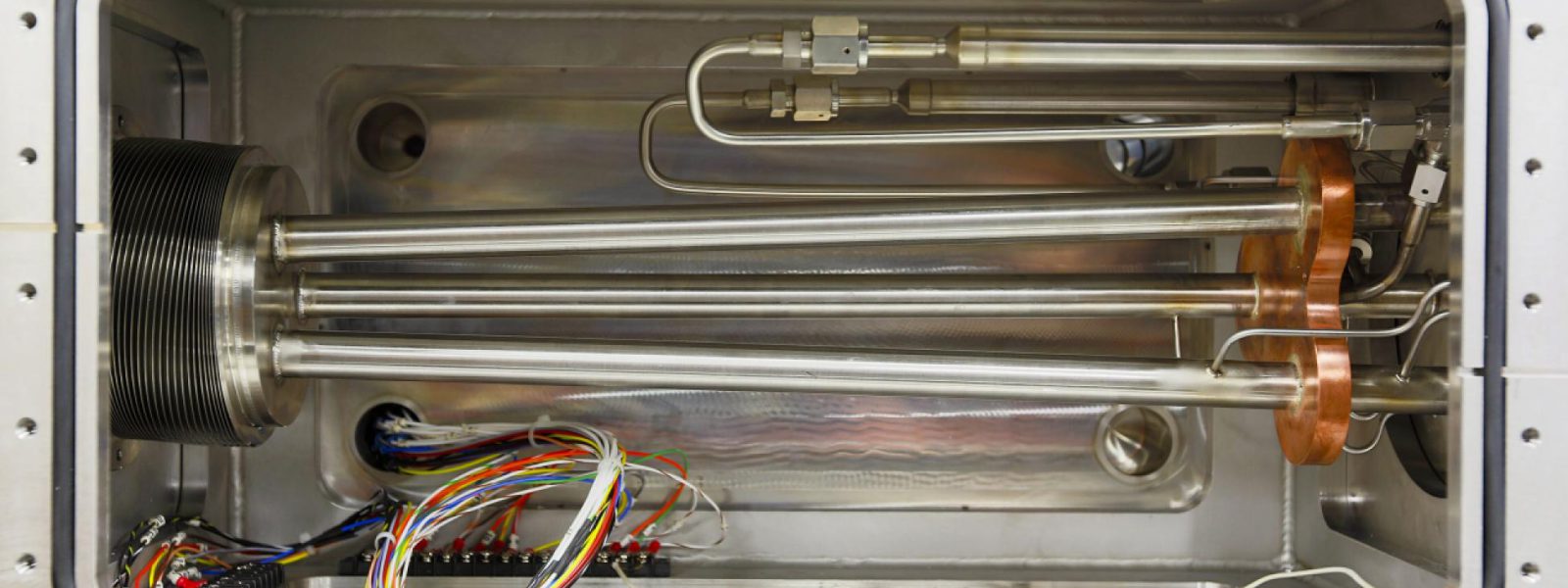

First-of-a-kind achievements have already emerged from the US ITER and ORNL team, including the largest cryogenic frozen hydrogen pellet ever formed and fired by a pellet injector “gun” (25 mm in diameter) and a novel three-barrel pellet injector for delivering the pellets to the plasma. The pellet guns use a gas propellant to fire pellets at 300 meters per second, or about 670 miles per hour. The team is now at work making even larger cryogenic pellets—up to 41 mm in diameter—that can still maintain the necessary speed to deliver material to the plasma within milliseconds of a disruption.

Large shattered cryogenic pellets are useful for the ITER system because they reduce the number of separate injector barrels required to deliver sufficient material to the plasma. However, the team has had to develop methods for consistently producing a large pellet that survives the acceleration by the pellet gun.

“As size goes up, removing heat from the inside of the freezing pellet becomes more difficult. When this happens, the pellet may not form properly, or it could fracture or break apart and might not get out of the barrel under pressure. You not only need to be able to make the pellet, you need to be able to fire the pellet,” said Mark Lyttle, a project engineer for the US ITER pellet injection and disruption mitigation systems.

There are some differences between massive gas injection and shattered pellet injection.

“The penetration of material is likely to be deeper with shattered pellet injection. How beneficial this is remains to be seen,” Baylor said. Experiments using the shattered pellet approach are planned for later this year on the DIII-D tokamak, operated by General Atomics for the Department of Energy in La Jolla, Calif.

The response time for delivering material to the plasma also is different for shattered pellet and gas injection.

“Gas dribbles in like water from a faucet, but a pellet goes into the plasma all at nearly the same time,” Baylor said. However, gas injection is a technique used successfully on other tokamaks, and that experience can be an advantage in an experimental device such as ITER.

For massive gas injection, a custom gas valve has been fabricated, and testing will occur later this year.

“This valve needs to be very fast and operate in a high magnetic field, so it has no magnetic components,” Lyttle said. The valve will first be tested at ORNL in the upcoming months and then ultimately will be tested in a magnetic field under ITER-like conditions.

“In upcoming experiments, we will use shattered pellet injection to study thermal mitigation. In the past on existing machines, only gas has been used for thermal mitigation studies,” Baylor said.

In past experiments on DIII-D, shattered pellet injection has also been shown to be effective for increasing the density to prevent runaway electron formation during a disruption. Operators can prevent runaway electrons forming by delivering as much material into the plasma as possible, as quickly as possible, so that there are more collisions between the electrons and the injected material.

“Even with large pellets, we still want to use multiple pellets for disruption mitigation for redundancy of pellets in case of failure. At this point, 20 milliseconds for thermal mitigation is the goal,” Baylor said.

To maintain the necessary pellet delivery speed for large pellets, the team also is testing combination pellets of neon and deuterium.

“Neon is a lot heavier than deuterium, so it is important to figure out the right mix for speed, and to confirm that proper freezing is occurring and the pellet does not shatter before it is intended to,” said Steve Combs, a senior scientist in the plasma technologies and applications group at ORNL. “The potential advantage is that we can make a faster neon-deuterium pellet. Neon is the preferred pellet material since it has significantly more particles for thermal mitigation as well as collisional damping of electrons.”

A multi-disciplinary team is developing prototypes, designing experiments and testing components. Trey Gebhart, a Ph.D. student in nuclear and mechanical engineering at Virginia Tech, is contributing to the team this summer by developing software that models large pellet formation.

US participation in ITER is sponsored by the DOE Office of Science (Fusion Energy Sciences) and managed by Oak Ridge National Laboratory in Tennessee, with contributions by partner labs Princeton Plasma Physics Laboratory and Savannah River National Laboratory. For more information, see usiter.org.

The Oak Ridge National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our times. For more information, see science.energy.gov.

Media Contact: Lynne Degitz