―Agatha Bardoel

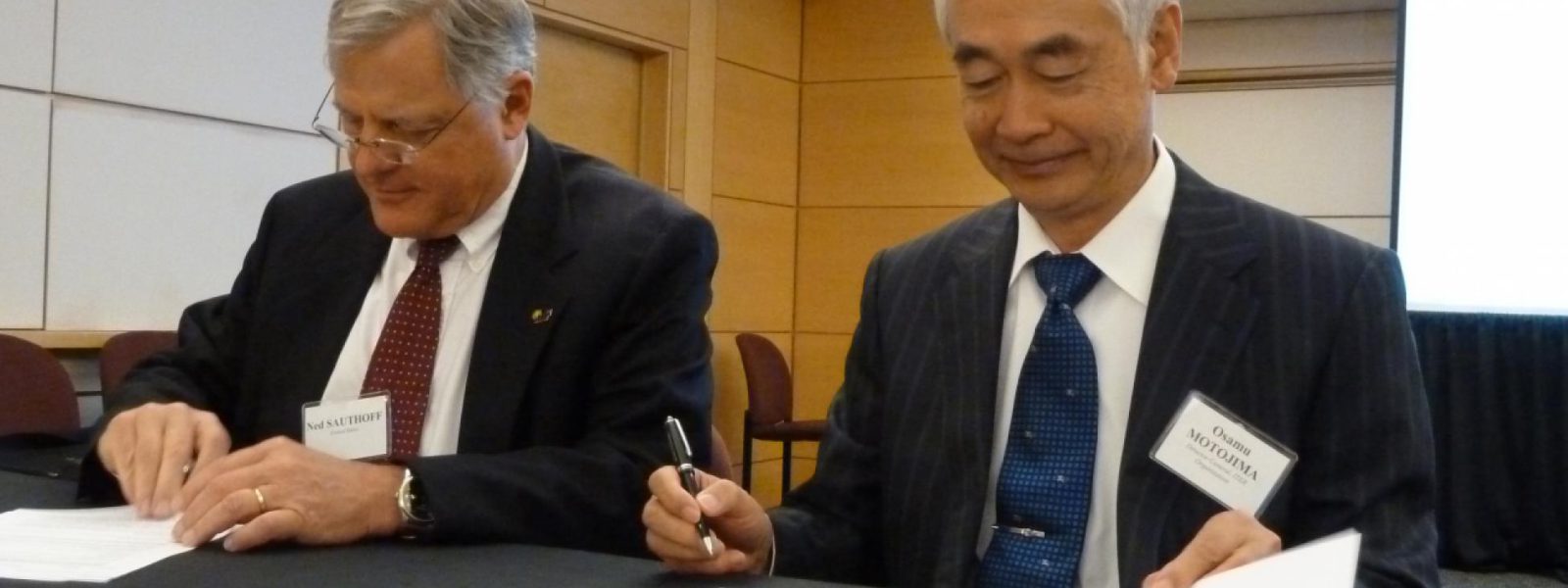

Understanding and monitoring electron density profile evolution and density fluctuations is essential for assessing the stability of fusion performance inside a tokamak. A new system that monitors electron density, known as the low field side reflectometer, is one of US ITER’s diagnostics contributions to the ITER tokamak now under construction in France. ITER Director-General Osamu Motojima and US ITER Project Manager, Ned Sauthoff signed the Procurement Arrangement for this diagnostic on June 20, 2012.

Greg Hanson of Oak Ridge National Laboratory’s Fusion Energy Division and Tony Peebles of the University of California at Los Angeles have been working on the conceptual design of the reflectometer with a team that includes staff from the University of California at Los Angeles, ORNL and Princeton Plasma Physics Laboratory.

ITER’s complex diagnostics are configured at ports in the vacuum chamber around the plasma vessel, to monitor and provide data over time of the evolution of plasma properties such as electron density and temperature.

Besides providing data on the electron density profile evolution, the new reflectometer will monitor small-scale density turbulence and larger scale magneto hydrodynamic (MHD) modes inside the plasma, such as fast-ion driven instabilities. Such instabilities can cause the ITER plasma to lose heat, particles, and momentum. It is important for researchers to understand and monitor the amplitude and spatial distribution of these instabilities, in order to project forward to the next-stage fusion reactor.

The new diagnostic is particularly important in monitoring phenomena of particular concern for ITER, so-called edge localized modes (ELMs) which trigger a transition from high to low plasma confinement. When this transition occurs, the energy released at the plasma edge can potentially cause damage to the plasma-facing surfaces. The new reflectometer diagnostic will monitor the magnitude of these ELMs as well as detect precursor signatures that can be used to control and mitigate their impact. High priority research continues on how best to minimize and avoid ELMS during ITER discharges.

Physically, the new diagnostic reflectometer is similar to radar detectors used by a highway patrol. It operates at the millimeter wavelength. At ITER, the millimeter wave sources (sophisticated versions of those found in microwave ovens) will be located in a room 40 meters from the ITER reactor, eliminating interaction with the radiation and thermal loads released by the plasma.

In practice, millimeter waves enter the ITER device along a corrugated waveguide, approximately six centimeters in diameter. An array of waveguide antennas located near the edge of the plasma provides the necessary frequency coverage and accommodation of plasma shape variations. The plasma retro-reflects the millimeter radiation launched from the waveguides, in the same way shortwave radio waves bounce back from the ionosphere.

The time delay generated by propagation to and from the plasma is dependent on the launch frequency – higher frequencies reflect from deeper in the plasma. Measurement of these time delays versus millimeter-wave frequency allows the electron density profile to be determined with high accuracy.

The new reflectometer will take a measurement of the electron density profile in the plasma every 10 microseconds, so that a virtually continuous monitor of the density profile can be obtained.

Media Contact: Lynne Degitz