―Agatha Bardoel

Oak Ridge National Laboratory’s Fusion Pellet Fueling Lab has been at the center of design and testing of plasma fueling systems for tokamak research applications for decades. Since the mid-1970s, lab researchers have been designing, testing, and contributing hardware for fusion magnetic confinement experiments here in the United States and around the world. As the US ITER project moves from design and testing of components to manufacturing, the lab is making prototypes for the ITER tokamak.

ORNL researchers David Rasmussen, Steve Combs, Steve Meitner, Larry Baylor, Charles Foust, Dan Fehling, James McGill, John Caughman, and Robert Duckworth are among the key players involved in testing pellet injector technology for fueling and for controlling the plasma. The technology then goes to plasma experiments for testing in tokamaks in real-time fueling environments.

The lab’s efforts include work for the JET (Joint European Torus) tokamak in the United Kingdom, currently the largest fusion experiment in the world; for the DIII-D tokamak operated for the US DOE by General Atomics in San Diego; and in the past, for collaborations with France’s Tore Supra and Japan’s Large Helical Device (LHD). When ITER is built in France, it will have a plasma volume that is eight times larger than the capacity of any current tokamak.

Current research continues on the following areas which are important for US ITER contributions to fueling, disruption mitigation, and vacuum systems:

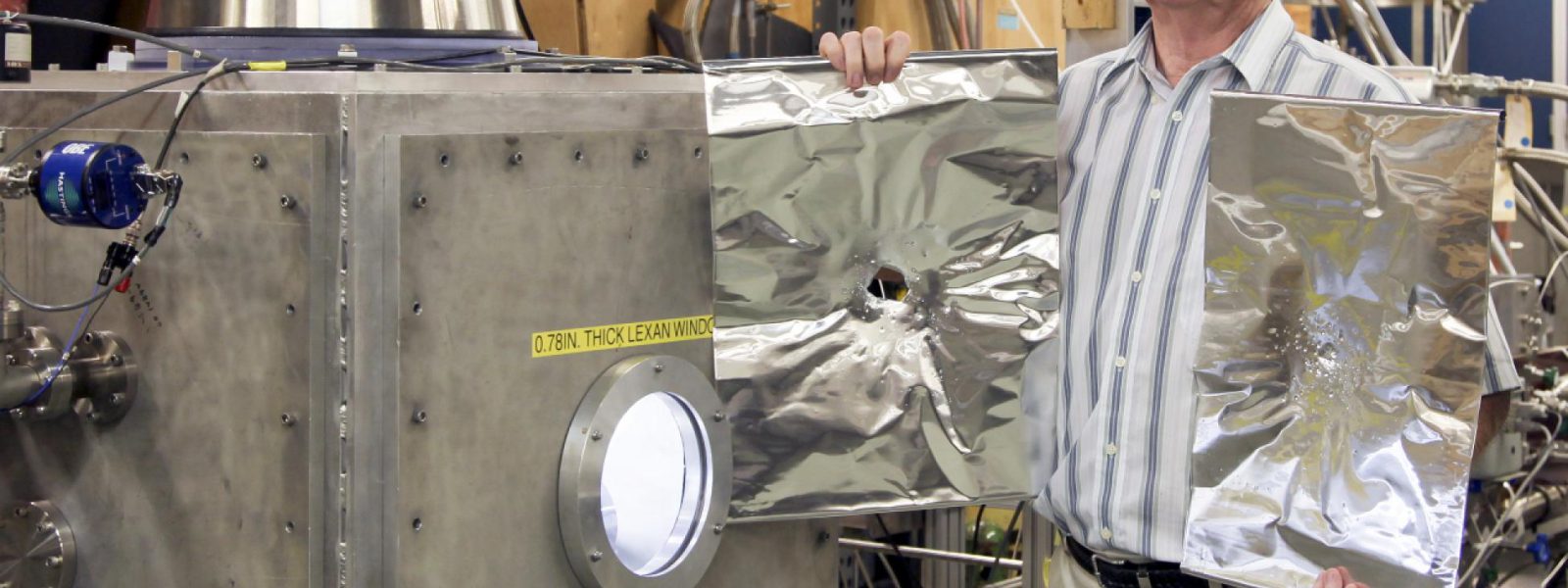

- Pellet Injectors. “The initial plan for ITER is to have two injectors,” says Steve Combs, a chemical engineer who has spent much of his career in the ORNL Fusion Energy Division developing pellet injectors and related technologies. One of the ITER pellet injectors is for fueling, using ~5.3 mm pellets; the other is for controlling the density at the edge of the plasma boundary by injecting relatively small pellets to produce small edge localized modes, or ELMs. Pellets for ELM pacing will be roughly 3 mm in size. “Large ELMs can damage the plasma facing materials in the divertor, so we must inject pellets at fairly high frequency,” says Combs. To better understand the potential of ELM pacing, an ORNL pellet injection system on DIII-D is being modified to inject relatively small deuterium pellets at 40–50 Hz; initial testing is planned for later this year. Pellet systems are also being designed and tested for plasma disruption mitigation. Large pellets, greater than the size of wine corks, and multiple injection sites are being considered for reducing the impact of plasma disruptions in ITER. Such a system is already installed on the DIII-D tokamak and has been successfully used in experiments, with more planned this year.

- Continuous Twin-Screw Pellet Extruder. A novel pellet extruder, designed by Steve Meitner and Larry Baylor at ORNL, is now being tested. This device provides a continuous stream of solid hydrogen (composed of hydrogen isotopes) to a secondary acceleration stage. A “cookie cutter” device punches out cylindrical “chunks,” and a propellant valve provides a light gas (typically hydrogen) to propel them into the plasma at speeds of a few hundred meters per second or greater. The pellets can be used for both fueling and ELM pacing.

- Massive Gas Injection Technology. An alternative massive gas injection system for plasma disruption mitigation has also been developed. Comparing results from this system with those from massive pellet systems will help researchers determine the best disruption mitigation design for ITER. The advantage of using gas is that it is conceptually a very simple system. However, maintenance would be problematic in the case of mechanical problems or any leakage from a close-coupled valve, since the gas valve must be located close to the tokamak to be effective. “At this moment it is not obvious what would comprise the optimal system,” Combs says. “Several groups around the world are looking at it. It has some high priority now for ITER.”

- Microwave Cavity Mass Detector. A prototype diagnostic to measure the pellet mass in flight has been tested in the ORNL fusion pellet fueling lab. The microwave cavity mass detector is currently the main diagnostic for recording real-time pellet mass, size, and speed. “This will tell the physicists how many particles are injected into the plasma at a given time,” Combs says. The detector measures the mass of each pellet emerging from the injector as it passes through a tuned resonant cavity that is optimized for performance at a specific frequency. As the pellet passes through the cavity, the cavity is detuned, producing an electrical signal that is proportional to its mass; the detector data also provide the pellet speed. Two detectors will be included downstream of the injector barrel on the ITER injectors. “The two prototype microwave cavities in the lab need some minor changes to be completely compatible with the tritium environment for ITER,” Combs says. “They look pretty good. They are essentially prototypes for ITER.”

- Cryogenic Viscous Compressor (CVC). The ITER vacuum system requires a roughing pump system that can pump the exhaust gas from the torus cryopumps to the tokamak exhaust processing plant. The gas will have a high tritium content and conventional vacuum pumps are not suitable for handling this radioactive isotope. A pump called a CVC is being designed for the ITER roughing system to pump from ~500 Pa to 10 Pa at flow rates of 200 Pa-m3/s. A unique feature of this pump is that it allows any helium in the gas to flow through the pump, where it is exhausted to the atmosphere. In the fusion pellet fueling lab, a small-scale prototype of the CVC is now being tested for heat transfer characteristics and compared to modeling results, to ensure reliable operation of the full-scale CVC. This research is being conducted under the direction of Mike Hechler, the vacuum pumping lead for US ITER. “We are helping the vacuum team with this,” says Combs. Nothing now exists anywhere in the world that will do this. They are getting ready to build a full-scale prototype module soon. If that works out well, they will then begin to design the final units for ITER.

“All these projects use common equipment here in the fusion pellet fueling lab, to save money,” notes Combs. “One day we run one or two experiments, and on another day, we run one or two other experiments. We work together as a team, and things work out just fine. We look forward to our components/systems being used in ITER. We have a real sense of pride in it. In the next five to six years, we have to get some real systems ready for ITER. We have to test them, and then we have to deliver reliable systems.”

Media Contact: Lynne Degitz

Source: US ITER