The United States has delivered the sixth and final module needed to complete the central solenoid magnet of the ITER tokamak. The event marks the culmination of more than a decade of engineering design and fabrication of a first-of-its-kind pulsed superconducting magnet that will sit at the center of the ITER tokamak.

“This is another example of how the ITER project is moving fusion technology and industry forward in the United States and the world, preparing us for a future with practical fusion energy,” said Kevin Freudenberg, the US ITER technical director. Freudenberg has been part of the US ITER project since 2007, when he started as the lead analyst for magnet systems.

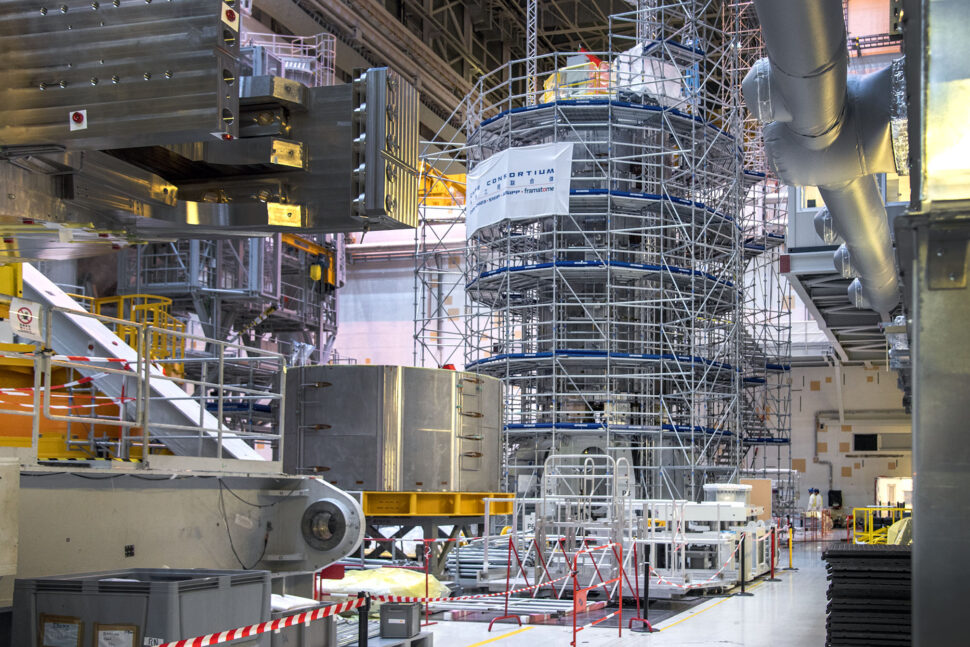

Currently, four of the six modules are stacked and connected in the ITER Assembly Hall. The fifth module has passed site acceptance testing and is being prepared to be added to the stack. The sixth module, which arrived in France at the port of Fos-sur-Mer this past week, is scheduled to be placed atop the stack early next year. (In addition, a spare module is scheduled to arrive at the ITER site at the start of the year.)

More than a dozen U.S. companies and organizations have contributed to developing and fabricating the central solenoid superconducting magnet.

Located across the nation, contributors include General Atomics in San Diego, California; ARMEC Corp in Knoxville, Tennessee; Climax in Newberg, Oregon; Cryomagnetics in Oak Ridge, Tennessee; Hamill Manufacturing Co. in Trafford, Pennsylvania; Kamatics Corporation in Bloomfield, Connecticut; Keller Technology Corporation in Buffalo, New York; Major Tool and Machine in Indianapolis, Indiana; National High Magnetic Field Laboratory of Florida State University in Tallahassee, Florida; Petersen, Inc., in Ogden, Utah; Precision Custom Components in York, Pennsylvania; Rhinestahl in Cincinnati, Ohio; Robatel Technologies in Roanoke, Virginia; and Superbolt, Inc., in Carnegie, Pennsylvania.

Read the full article.

The sixth module for ITER's central solenoid module has completed its transatlantic journey from the United States to the French port of Fos-sur-Mer. Photo: ITER Organization

The sixth module for ITER's central solenoid module has completed its transatlantic journey from the United States to the French port of Fos-sur-Mer. Photo: ITER Organization