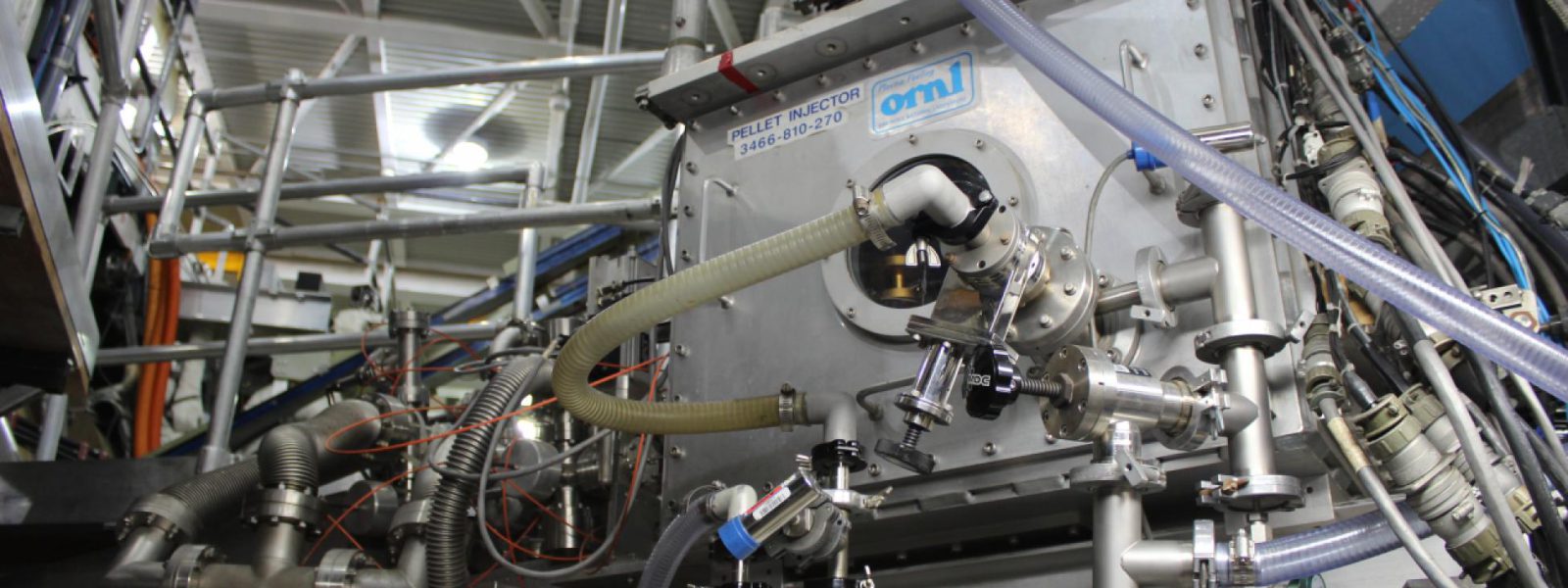

Researchers at Oak Ridge National Laboratory developed a continuous extruder for fusion fuel and are advancing state-of-the-art fueling and plasma control for the ITER international fusion reactor now under construction in France. US ITER is managed by Oak Ridge National Laboratory for the U.S. Department of Energy.

Reliable, high-speed continuous fueling is essential for ITER to meet its goal of operating at 500 MW for several minutes at a time. The latest pellet injection experiments using US ITER prototype designs were performed during the week of July 22, 2013 at the DIII-D tokamak operated by General Atomics in San Diego, Calif. The conceptual design review for the ITER pellet injection system was completed earlier this year, and preparations are now underway for full-scale prototype testing. All of these efforts bring ITER a step closer to demonstrating fusion as a viable carbon-free energy source.

The ITER machine will also be a tokamak—at a much larger scale—containing hot plasma within magnetic fields. The ITER tokamak is designed to produce a burning plasma, where the energy of the fusion reactions keeps the plasma hot. The task of the pellet injection system is to provide plasma fueling for ITER, while also lessening the impact of plasma instabilities due to large transient heat loads.

The ITER pellet injectors must operate continuously, which is very different from most existing pellet injectors for tokamaks. The ITER machine also requires a higher rate of pellet fueling throughput.

Dave Rasmussen, team leader for the US ITER pellet injection and disruption mitigation systems, says that “the ITER pellet injectors will require an increase in the deuterium-tritium mass flow and duration by a factor of 1000 compared to present systems.”

To produce the pellets, researchers developed a twin-screw extruder which shapes a continuous ice stream of deuterium-tritium fuel into specific diameters and lengths.

“There are existing extruders used on tokamaks today, but they cannot meet the requirements of ITER. On most current installations, extruders have only needed to supply a few seconds of fuel pellets at a time, but the ITER tokamak will require almost an hour of a continuous ice stream for pellet injection. The ORNL twin-screw extruder is designed to meet the requirements of ITER,” notes Mark Lyttle, a project engineer for the US ITER pellet injection and disruption mitigation systems.

Multiple pellet injectors will be installed on the ITER tokamak, with up to two injectors at each of three locations on the machine. Some locations will be used more for fueling while others will be deployed for lessening the impact of plasma instabilities known as edge localized modes (ELMs) by a technique called “pellet ELM pacing.” The pellet injector can also insert impurity pellets made of argon, neon, or nitrogen into the tokamak for plasma impurity studies. The pellet injectors must also be able to handle tritium safely; tritium is a radioactive isotope of hydrogen with a half-life of about 12 years.

“There is a 30 year technology development history at ORNL behind the ITER pellet injection design,” says Lyttle.

The pellet twin-screw extruder now under testing is 1:5 scale of the extruder that will be installed on the ITER tokamak. However, it is more than physical size that distinguishes this prototype from the final design. The ITER extruder will have a much greater cooling and throughput capacity.

The main areas for attention during the next stage of development are the twin screw extruder with pellet cutting and acceleration hardware, overall system design for safety and code compliance, and the design and development of a recirculation system for the pellet ice. Since tritium is rare, expensive and radioactive, recirculation of any unused pellet ice is a must. The next few months will be used to design a system to capture and reuse any pellet ice that does not get injected into the tokamak.

“We do plan to build a full-scale prototype and test it at the Spallation Neutron Source cryogenic facility at ORNL, where we have access to a supply of supercritical helium. Supercritical helium at only 5 degrees above absolute zero is used as the coolant to form the pellet ice and we are lucky to have one of the few facilities in the world that can supply our needs here at ORNL” says Lyttle.

Testing is underway now on the smaller prototype utilizing other cooling methods, but more intensive testing on reliability and performance will occur at SNS. Testing on the scale prototype at SNS is planned for the summer of 2014, with a full scale prototype in 2015.

Other key upcoming activities for researchers and engineers are tests of a propellant gas recirculation loop for the pellet injection system using a tritium-compatible vacuum pump. The recirculation loop supplies the pressurized propellant gas and assures that the gas used to accelerate the pellets is not injected into the vacuum chamber of the ITER tokamak during the fueling process.

“Initial tests on the pumping speed look promising,” observes Lyttle. This pump has been tested with helium gas and soon will be tested with hydrogen gas. Ultimately, the pump and loop will undergo a multi-year “lifetime” test to assure its readiness for the ITER pellet injection system.

The ITER requirements outline an expectation of 99.9% availability of the entire pellet injection system, which includes the tritium compatible pump, during tokamak operations.

“Because the pellet injection system will be sealed in its own cask when it is installed, it will be very difficult to access during operation. That is why the reliability requirements are so high,” says Lyttle.

Media Contact: Lynne Degitz